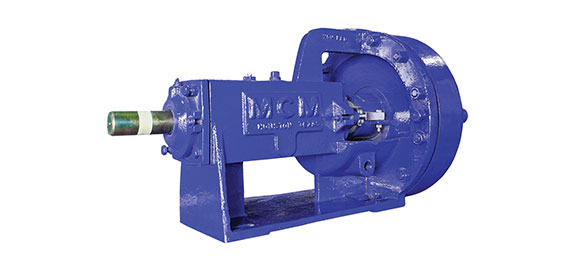

MAXUM OH1

Heavy-Duty, Horizontal End-Suction Pump

Our heavy-duty, horizontal end-suction pump for handling hydrocarbons and process industry applications, includes flows up to 11,000 GPM.

Our heavy-duty Pump

Designed as a foot-mounted version of our API centerline-mounted Maxum OH2, the Maxum OH1 is an industry workhorse. The Maxum OH1 can be motor, engine, or turbine-driven and is ideal for water, hydrocarbons, caustic and acid applications. With hydraulic performance to 11,000 GPM and 720 feet of head, this pump family is available in carbon steel, 12% chrome, 316L and duplex stainless steel, according to standard API material codes. In addition to these, higher alloys such as Alloy 20, Hastelloy B or C, Monel and titanium are also available.

As standard these units come with oil-lubricated bearings with labyrinth isolators, and connections for temperature probes. Common options include various cartridge seals and API piping systems. Flanged or NPT auxiliary connections, cooling jackets, spacer couplings, and various levels of performance testing are also available, depending on users’ requirements. Available heavy-duty baseplates result in maximum flange loadings that meet or exceed the requirements of API 610. With some of the most efficient hydraulics in the industry, the Maxum series offers reliability, low lifetime cost, and lasting value that has made Carver one of the most trusted names in pumps.